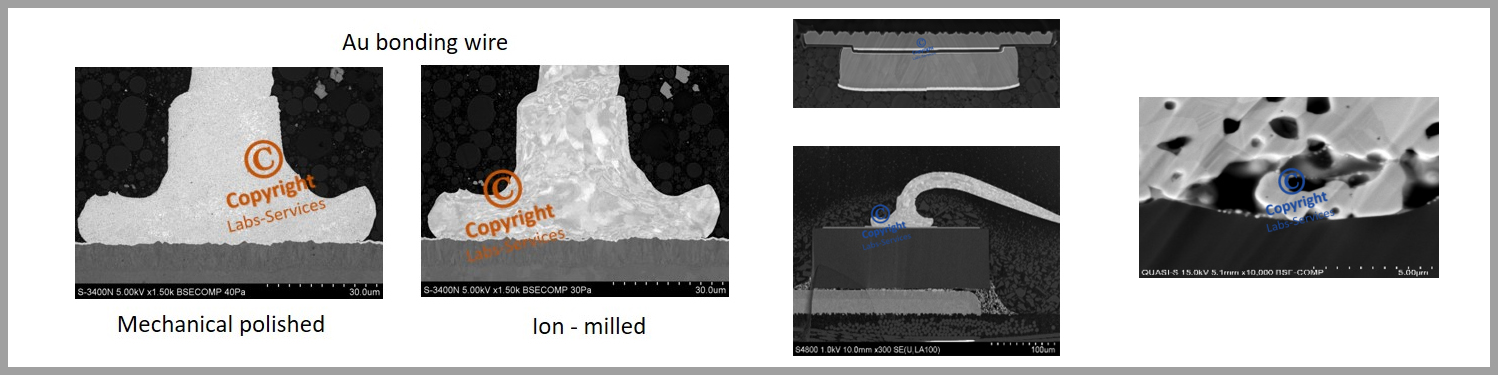

Conventional mechanical polishing or cutting techniques on soft, composite materials apply significant lateral sheer forces to the sample and often result in cross-section surface artefacts such as scratches, smearing, wash-out of softer materials, delamination and other damage.

In contrast, ion beam sputtering is a stress-free physical process whereby atoms are ejected from a target material due to bombardment of the target by energized particles. Both Flat-Milling and Cross-Milling are deployed to provide perfect surfaces for further analysis. It is used particularly on difficult edges and corners where mechanical preparation could distort the evidence.

Any materials, like powder, printing paper, fibre, polymer, IC package, BGA ball etc.